My research primarily focuses on perception, decision-making, planning, and control in autonomous driving.

All of my research is closely connected to real-world applications, as I firmly believe that the true value of research lies in its practical deployment and societal impact.

Research Projects

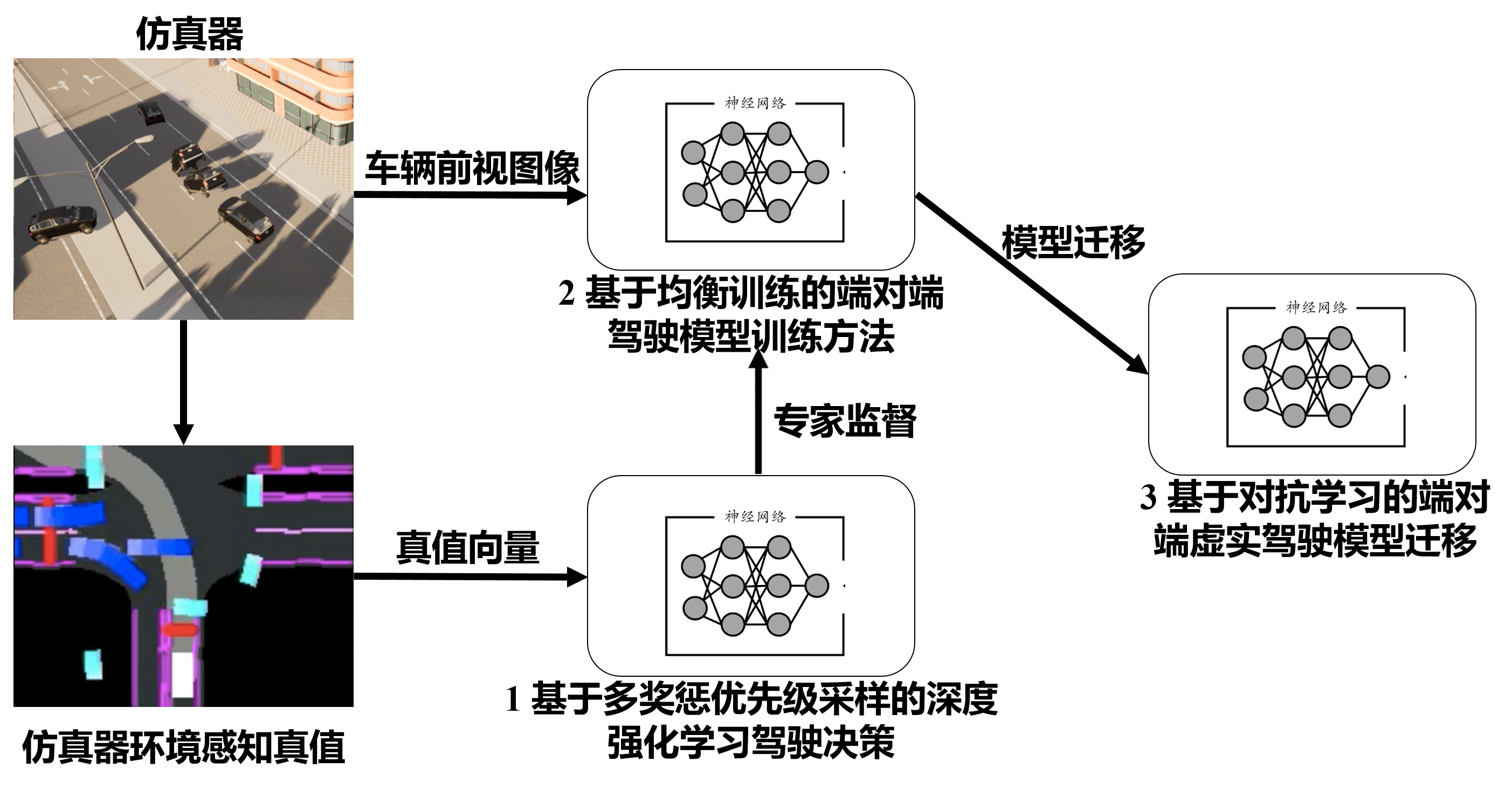

- 2023.01–2025.12: National Natural Science Foundation of China (No. 62203301)

- Research on End-to-End Learning Methods for Intelligent Vehicles Based on Virtual–Real Transfer

- 2021.06–2024.06: Shanghai Talent Development Fund

- Research on Key Technologies of Unmanned Logistics Vehicles for Industrial Parks

- 2021.06–2024.12:

- Principal Investigator, Research on Smart Takeaway Delivery Unmanned Vehicles

- 2023.06–2024.12:

- Technical Lead, Project on the Design and Development of Software Systems for New Energy Intelligent Connected Vehicles

- 2022.06–2023.06:

- Technical Lead, Project on the Deployment and Adaptation of 100 Unmanned Logistics Vehicles for Shanghai Jiao Tong University

- 2022.06–2023.06:

- Technical Lead, Project on Decision-Making and Planning Systems for Intelligent Connected Vehicles

- 2019.12–2021.06:

- Technical Lead, Project on 5G Cloud-Controlled Unmanned Logistics Vehicle Intelligent Systems

Industrial Applications

- Self-Driving Logistics Vehicles

- My team has developed full-stack software and algorithms for unmanned logistics vehicles, achieving large-scale deployment of over 300 vehicles across multiple factories, including SAIC-GM-Wuling and CATL’s Sichuan plant.

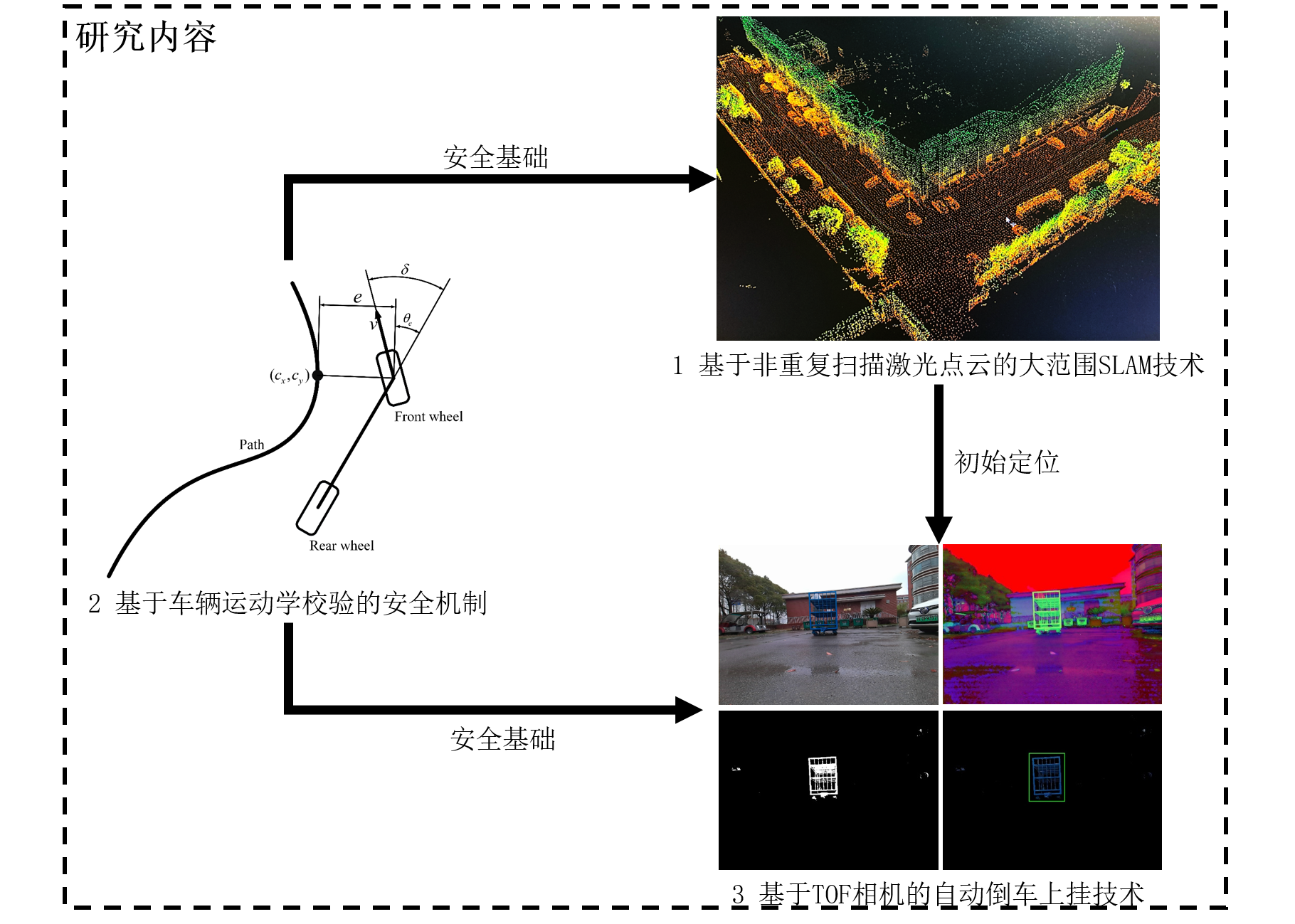

- Perception-based Autonomous Forklifts

- Traditional unmanned forklifts rely heavily on high-precision localization systems.

My team developed a perception-driven autonomous forklift using non-repetitive LiDAR scanning technology.

This system achieves a natural localization accuracy of ~5 cm and an operational precision of 2 cm, and is currently deployed for outdoor unloading operations at SAIC-GM-Wuling.

- Traditional unmanned forklifts rely heavily on high-precision localization systems.

- Newly Assembled Vehicle Transfer Robots

- Traditionally, newly assembled vehicles had to be manually moved off the production line, which was time-consuming and labor-intensive. Our team developed an autonomous transfer robot capable of seamless indoor–outdoor navigation, now deployed at SAIC-GM-Wuling’s island-style factory.

- Autonomous Sweeper Robots

- Developed a compact autonomous cleaning robot equipped with top-view LiDAR for natural navigation and automatic cleaning in complex environments.

- Unmanned Logistics Full Chain

- By integrating autonomous forklifts, unmanned logistics vehicles, and AGVs, our system enables a fully automated logistics chain—from unloading, to material transfer, to in-line AGV operation—currently deployed on SAIC’s engine manufacturing line.